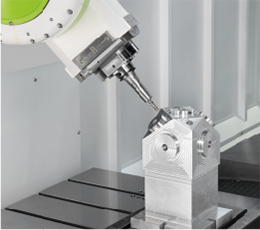

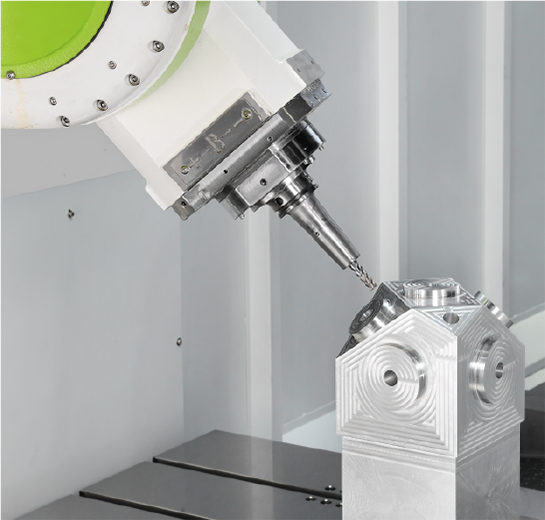

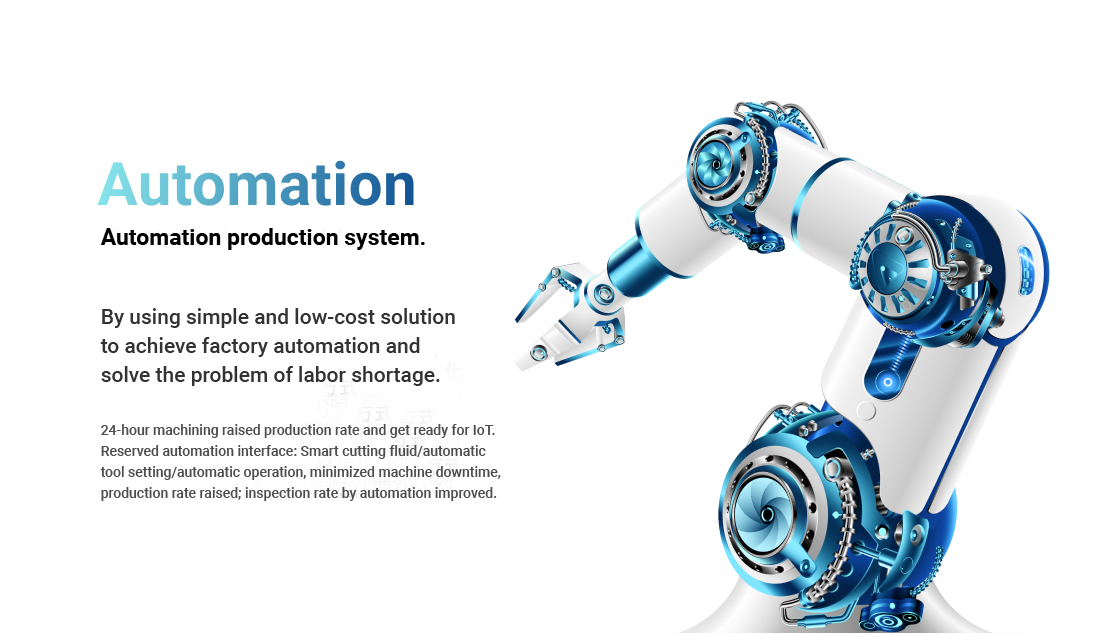

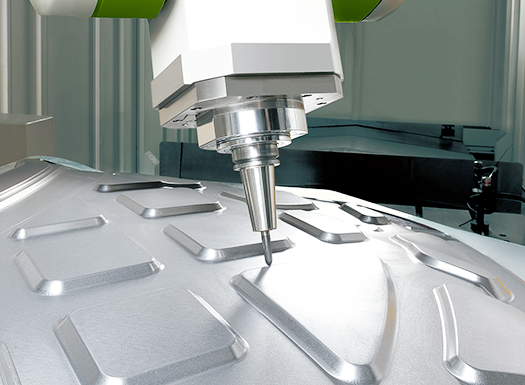

High Efficiency for Aerospace Components, High Speed 5 aixs Machining Center

Reach the next level of machining

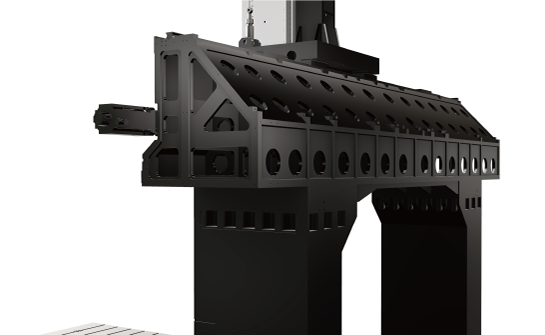

1. Taiwan made 5 axis head :High rigidity FORK structure design with high rigidity and high accuracy.

2. The size of machine head section is 540 x 521 mm, chamfer design inside the stock, machine head rigidity and strength can be boosted.