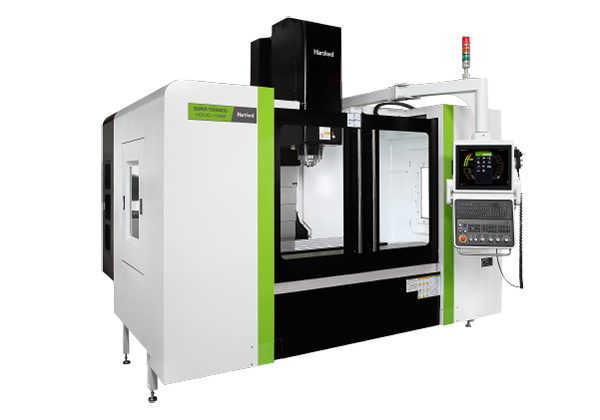

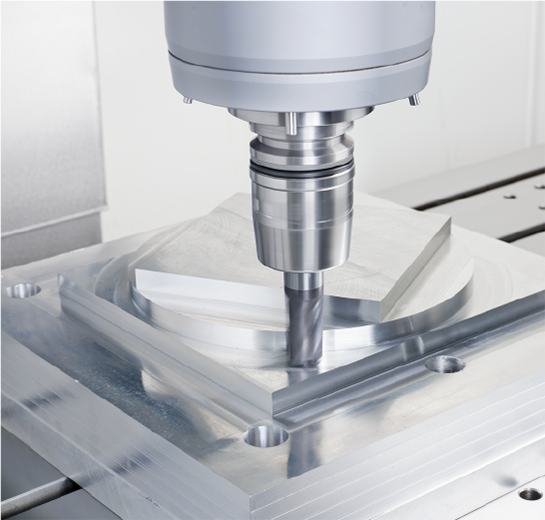

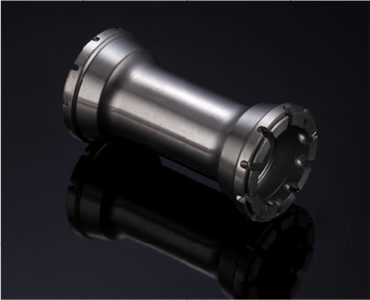

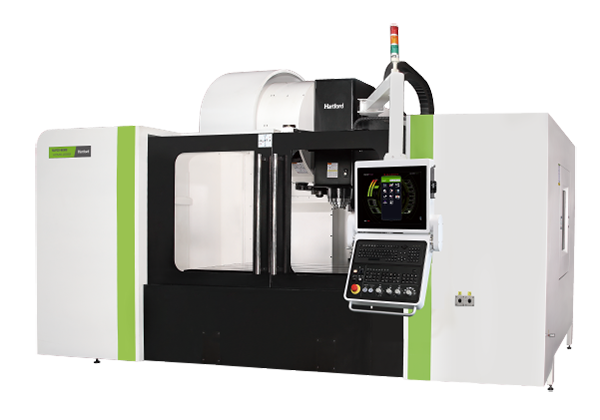

High rigidity & One-piece design for spindle housing and casting iron

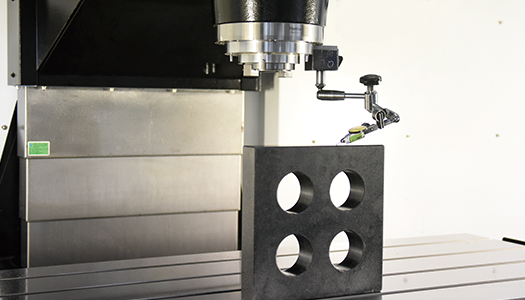

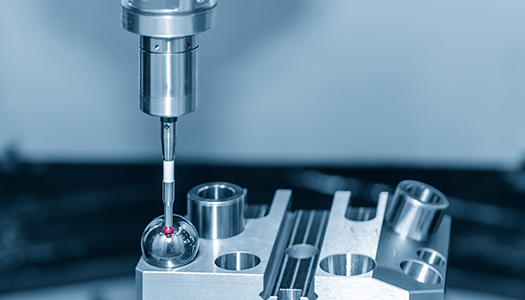

Optimum structural stability with Air Suspension & High-precision spindle

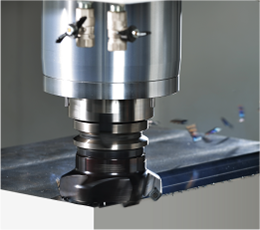

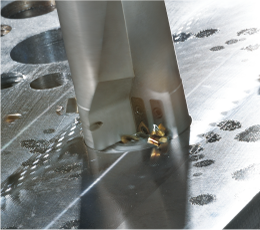

Enhance cutting accuracy, heavy cutting efficiency and extend life of guideway

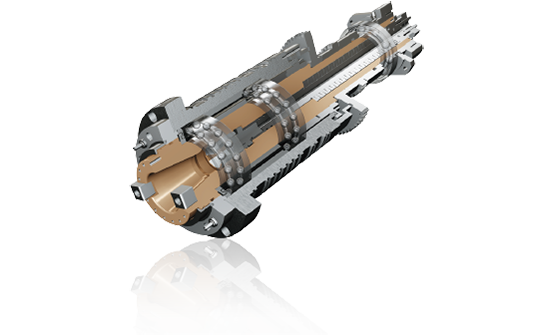

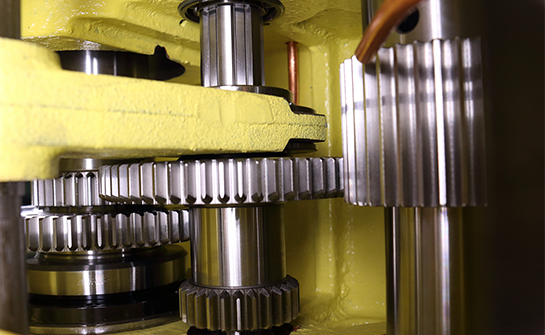

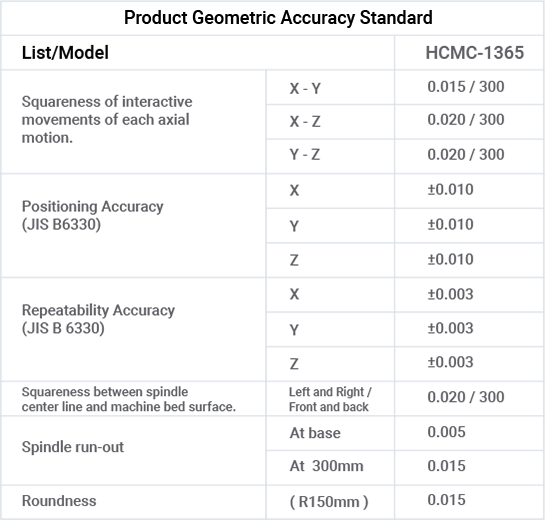

1. Self-made Gear head, deflection within average 9μm. (300L)

2. Reduce Environment thermal issue during machining, ensure thermal displacement within 15 μm while temperature difference within 8℃

3. Air Suspension function make 50% Quadrant Error reduced and 30% reduction in backlash error

4. High rigidity & One-piece design for spindle housing and casting iron, spindle thermal is within 9.5℃