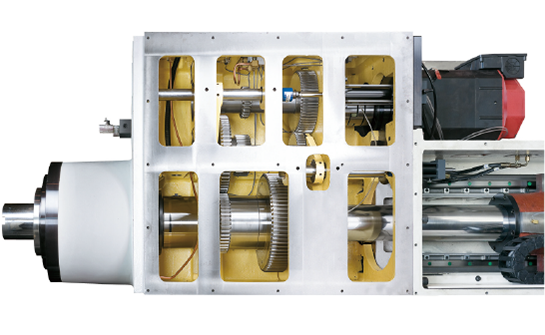

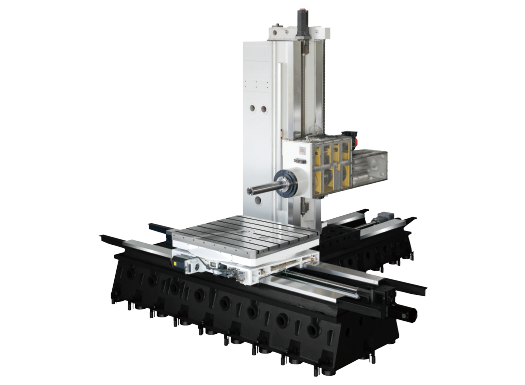

High Rigidity, High Precision

Tough, rugged and durable for PBM series

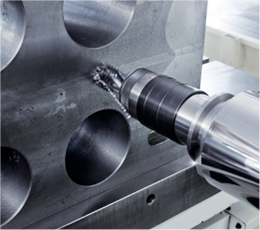

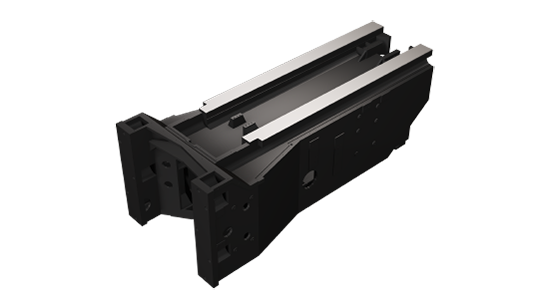

1. Oversized column design

For greater stability during cutting

Span between box guideways: 780mm

Box guideway thickness: 100mm

Box guideway surface width: 180mm

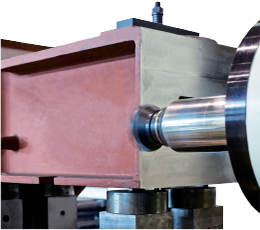

2. Specially design on front & rear base structure

Widen base design, span between box guideways 1140mm

Box guidway width: 200mm (front base)

Box guidway width: 250mm (rear base)