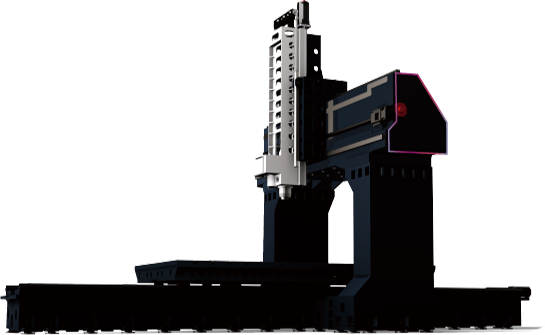

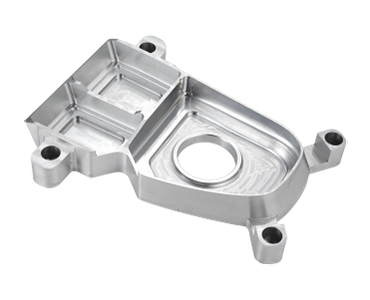

HSA 5 Faced Series = High Rigidity + High Precision

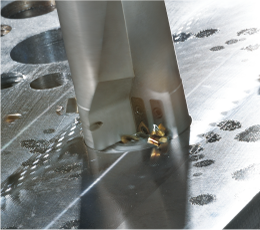

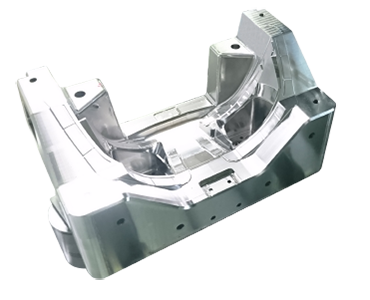

Fantastic performance for various machining application

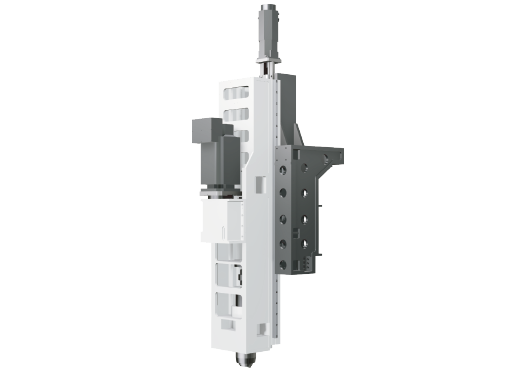

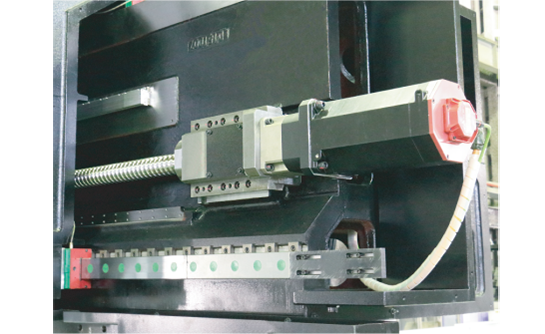

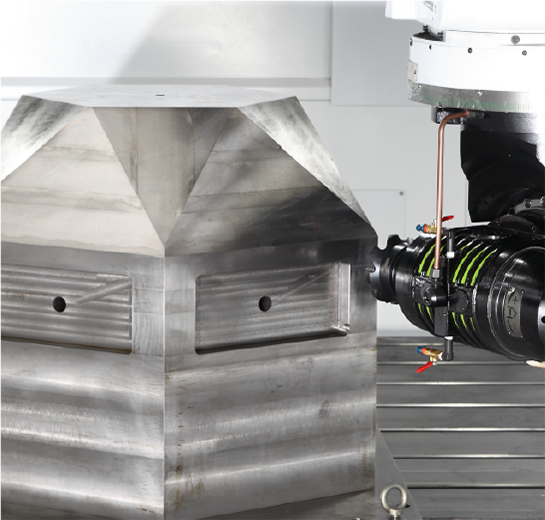

1. Z-axis four linear guideways three binding structure patented technology, two-way support provides 20% rigidity while cutting, bring you excellent performance.

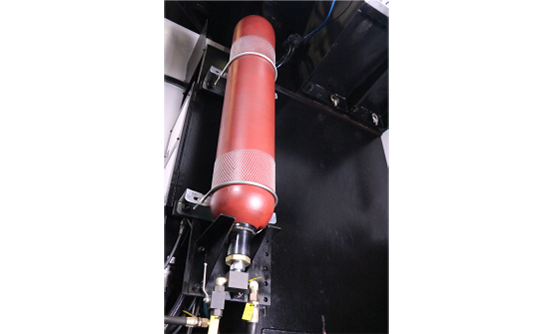

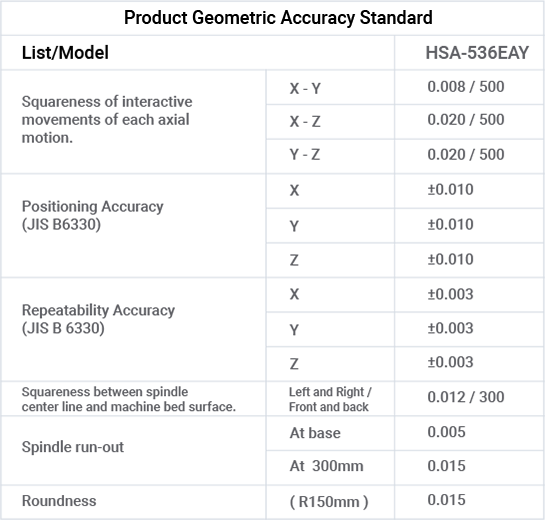

2. Multiple choice of spindle e.g. self-made gear head 8000 rpm.

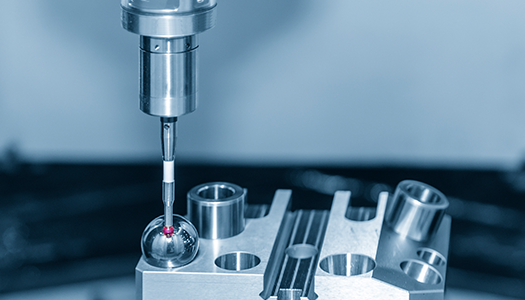

3. Self-made spindle, deflection within 5μm.

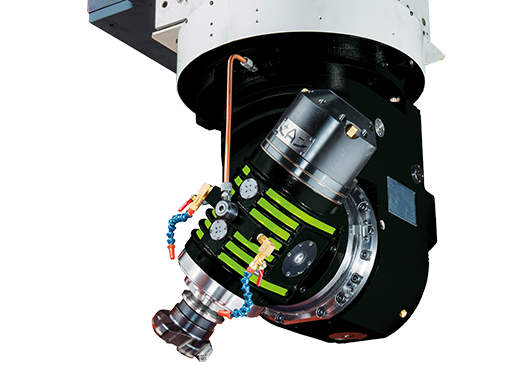

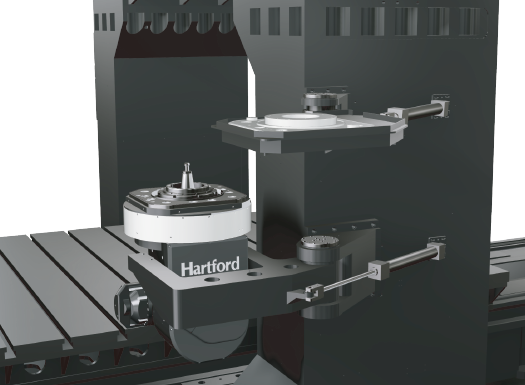

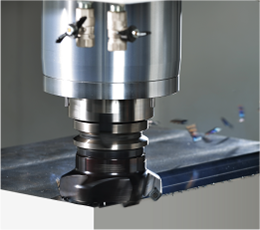

4. Complete angular head design package to meet wide range of processing needs.

5. Combined with automated switching head compartment and vertical and horizontal tool change system, to provide highly efficient versatile processing.