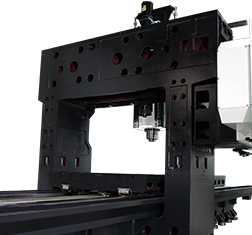

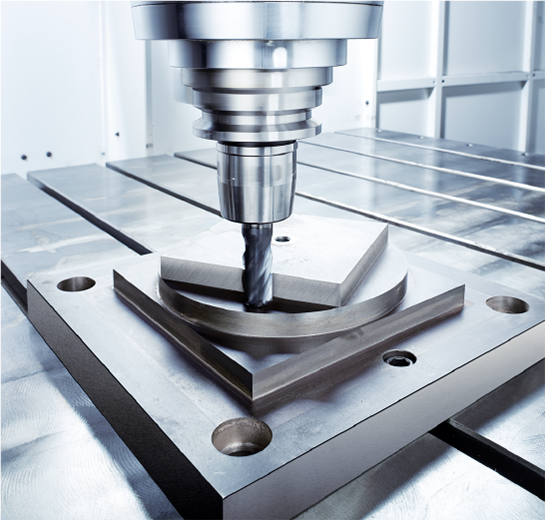

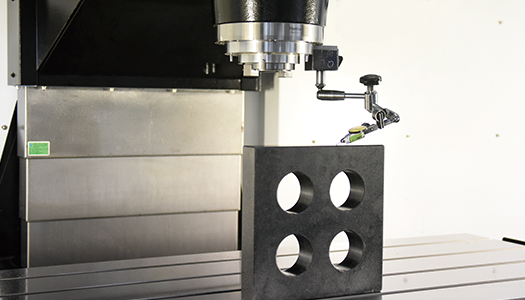

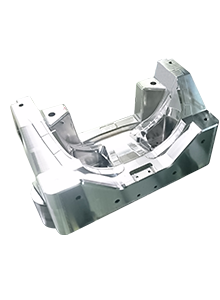

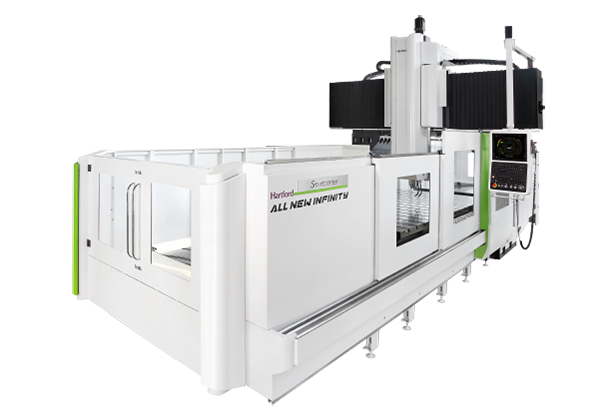

HSA series = high rigidity + high-precision

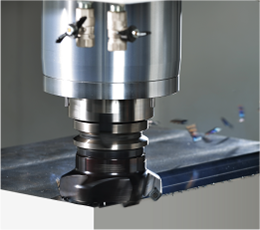

Fantastic performance for any machining application

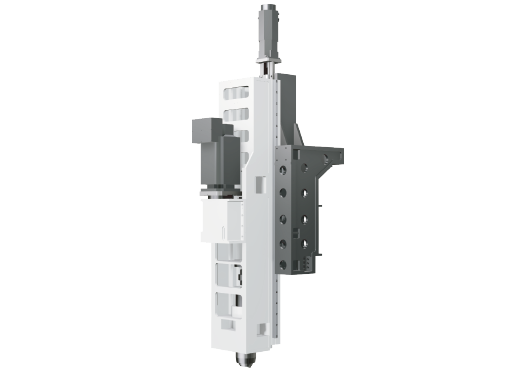

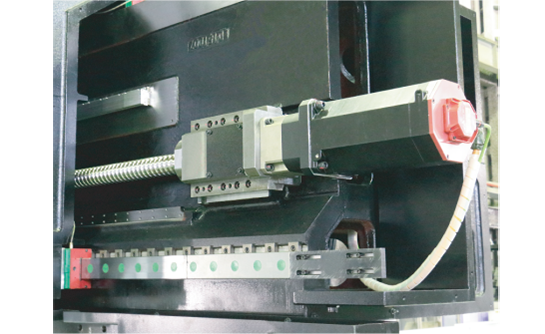

1. Z-axis four linear guideways three binding structure patented technology, two-way support provides 20% rigidity

while cutting, bring you excellent performance.

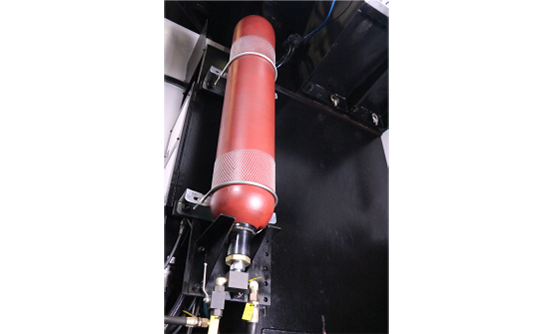

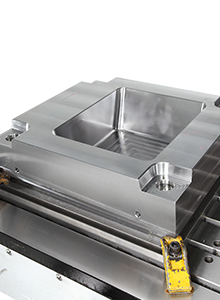

2. Multiple choice of spindle , ex. #40, #50, gear head 8000 rpm

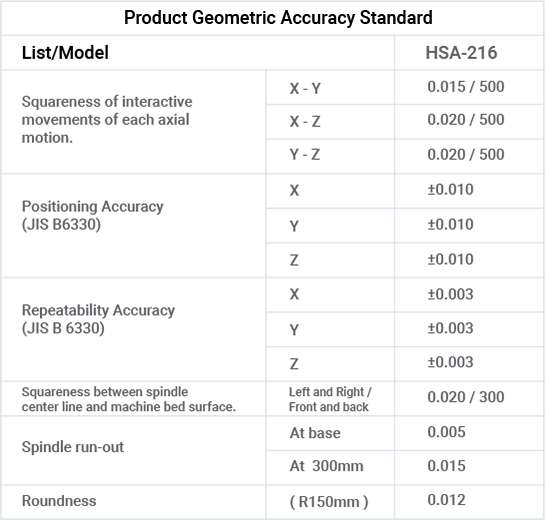

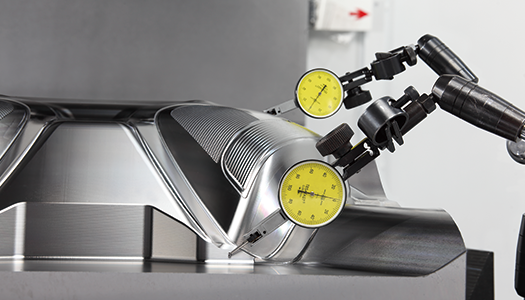

3. Self-made spindle, deflection within 5μm.