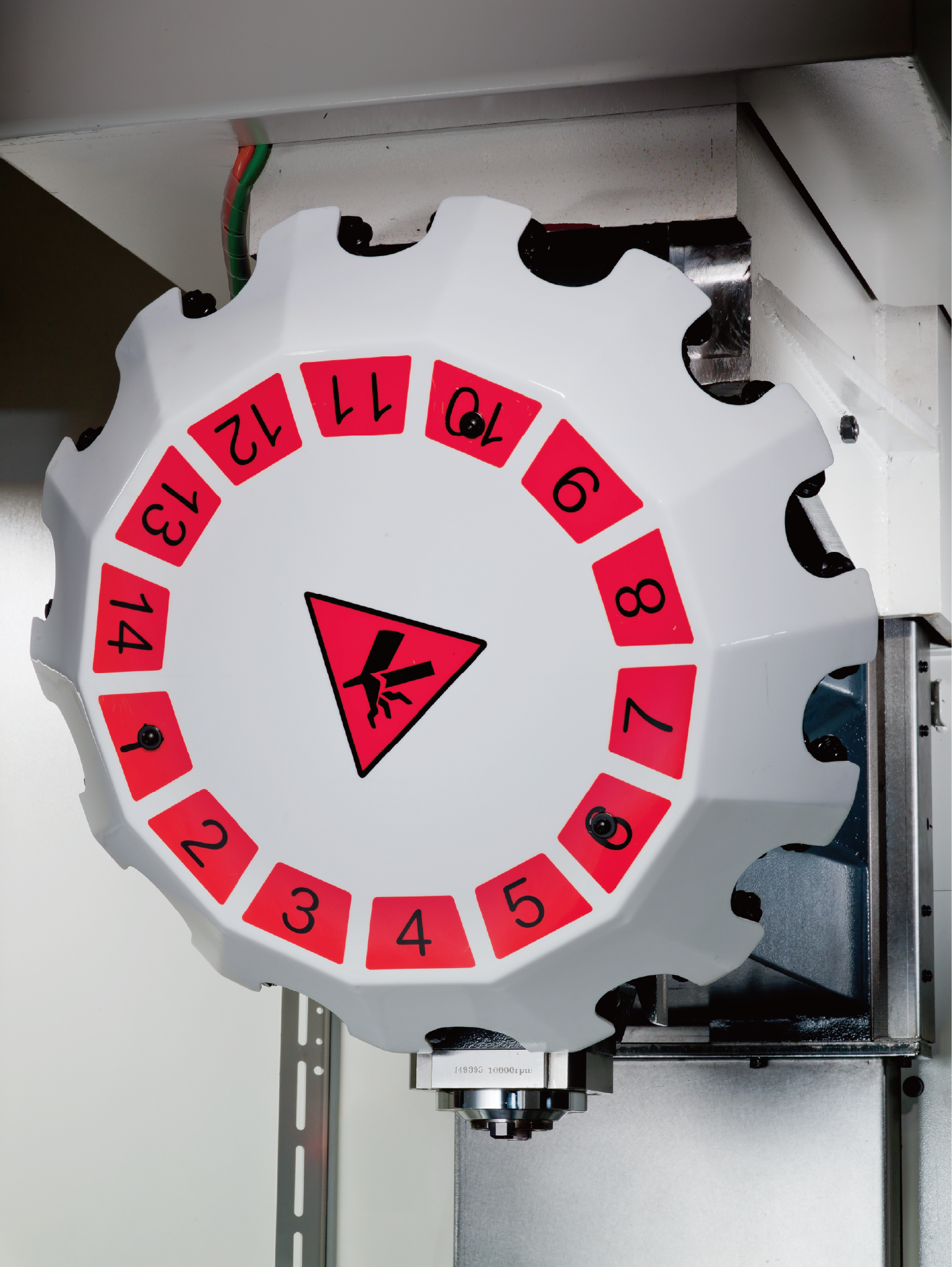

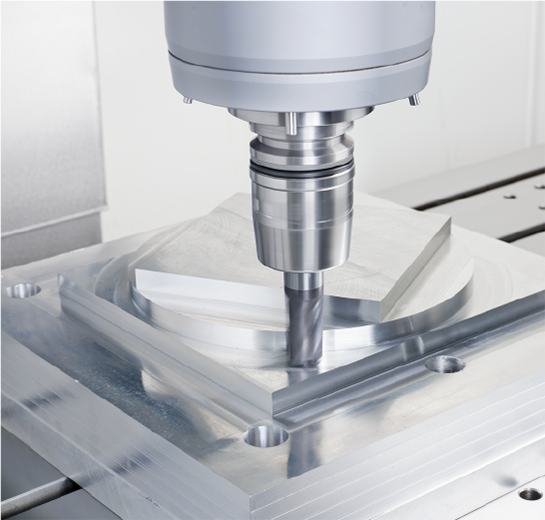

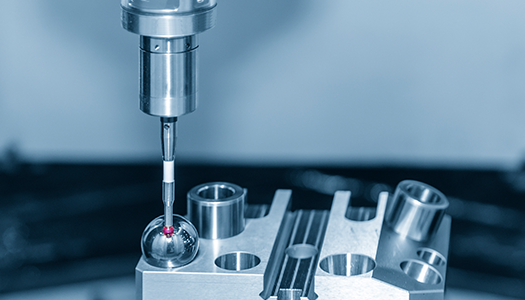

High-Rigidity Direct-Drive Spindle Head

Effectively avoids the noise, backlash, and vibration commonly found in belt-driven and gear-driven spindles.

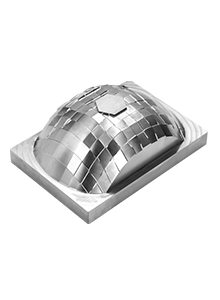

- High-precision machining performance meets the demanding accuracy requirements of the automotive parts, electronics, and optoelectronics industries.

- Optional 12,000 / 20,000 rpm low-inertia spindle motor for enhanced high-speed machining capability.

- Lightweight and energy-efficient motor design shortens acceleration and deceleration time, improving overall machining efficiency.